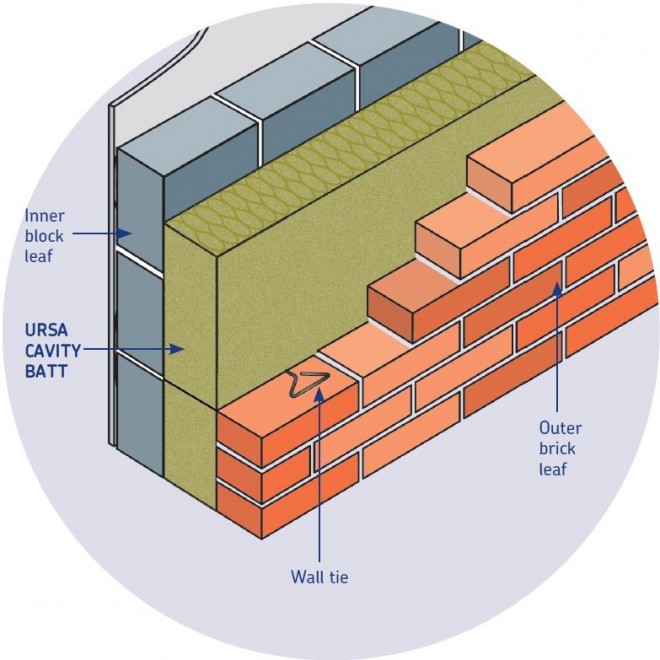

Masonry Cavity Walls

URSA CAVITY BATTS are suitable for both full and partial fill masonry cavity walls and have BBA approval. Fully filled cavity wall systems offer the most cost effective solution for a given U-value and can easily achieve current and proposed Building Regulation requirements. Our new, longer CAVITY BATT means 12% fewer slabs to install and up to 50% more product per pallet.

Two grades of URSA CAVITY BATT are available;

URSA CAVITY BATT 32 - thermal conductivity 0.032 W/mK.

URSA CAVITY BATT 35 - thermal conductivity 0.035 W/mK.

BBA Certificate 09/4624.

Design

URSA CAVITY BATTS are suitable for both full and partial fill systems. The batts may be used in any exposure zone in walls up to 25m high.

Rainwater penetration may be avoided by ensuring the correct use of lintels and cavity trays with appropriate stop ends.

Work undertaken by the BRE has identified the importance of good workmanship and the following points must be carefully considered;

- Ensure the residual cavity is kept clean and free from mortar dropping and other debris.

- Clean the top edges of the URSA CAVITY BATTS and the wall ties before installing the next row of slabs. The use of a timber cavity board is recommended to help keep this area clean.

- Do not push slabs down into a partially built section of cavity wall as this may dislodge mortar and bridge the cavity.

- Small, cut sections of slab should be installed with the face against the masonry i.e. with the fibres running vertically.

- Carefully cut, rather than tear, the slabs to fit around wall ties and other penetrations that cross the cavity.

Installation

The wall may be constructed leading with either leaf. It is good practice however to lead with the outer leaf as this allows the mortar joints on the cavity face to be cleaned and to check that the joints are all fully filled. The usual procedure for construction is;

- The leading leaf of masonry, ideally the outer leaf, is built with the first row of wall ties at 600mm centres where the insulation is to begin.

- The first row of URSA CAVITY BATTS, cut to size if necessary, may begin below the DPC in order to offer edge insulation to the floor.

- The inner leaf is then built, normally level with the top of the URSA CAVITY BATTS. It is permissible to build the outer leaf one brick higher to secure the next row of slabs – ensure mortar is cleaned from the cavity face.

- Raise the leading leaf to the level of the next row of wall ties, normally at 450mm vertical centres and 900mm centres horizontally. Ensure that the drip is positioned at the centre of the cavity and that the ties slope down towards the outer leaf. Excess mortar should be cleaned from this leaf before fitting the URSA Cavity Batts onto the lower ties.

- URSA CAVITY BATTS may be installed in two or more layers if a very low U-value is required. Stagger the joints in each layer to ensure the best thermal performance.

- The outer leaf is then built to the level of the top of the slabs and the process repeated.

- The subsequent rows of slabs should be fitted with vertical joints staggered i.e. brick bond with all joints tightly butted. Batts with damaged edges or corners should not be used.

- As work proceeds ensure that the top edge of the URSA CAVITY BATTS is clean and free from mortar droppings. The use of a cavity batten will help to protect the slab edges as the next section is built.

- Cut sections of slab may be required around openings or at corners. It is essential that these be cut accurately to fill the space they are intended for and are adequately secured.

- Ensure that partially completed walls are protected from inclement weather (wind, rain and snow) and at the end of the day’s work.

URSA CAVITY BATT 32 U-values

103mm brick, URSA CAVITY BATT 32, 100mm block & plasterboard on dab.

U-value (W/m²K)

| Block Type | 100mm | 125mm | 150mm | 175mm | 200mm |

| Aircrete Block (0.15 W/mK) | 0.24 | 0.20 | 0.17 | 0.15 | 0.14 |

| Light Agg Block (0.34 W/mK) | 0.26 | 0.21 | 0.18 | 0.16 | 0.14 |

| Medium Block (0.57 W/mK) | 0.26 | 0.22 | 0.19 | 0.16 | 0.14 |

| Dense Block (1.13 W/mK) | 0.27 | 0.22 | 0.19 | 0.17 | 0.15 |

Multi-Layer Systems

250mm URSA CAVITY BATT 32, U-value ≤ 0.12 W/m²K

300mm URSA CAVITY BATTS 32, U-value ≤ 0.10 W/m²K

For further information and more U-values see our technical brochure in the Documents section. Alternatively please contact URSA Technical Department.

URSA Masonry Cavity Wall Psi-values

| Description | U-value (W/m²K) | Psi-value (W/mK) | Temp. factor | Download |

|---|---|---|---|---|

| 100mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.23-0.24 | 0.053 | 0.90 | |

| 100mm URSA Cavity Batt 32 Light Block (0.31) | 0.26 | 0.055 | 0.90 | |

| 100mm URSA Cavity Batt 32 Light Block (0.45) | 0.26 | 0.057 | 0.90 | |

| 100mm URSA Cavity Batt 32 Medium Block (0.75) | 0.27 | 0.060 | 0.91 | |

| 100mm URSA Cavity Batt 32 Dense Block (1.30) | 0.27 | 0.063 | 0.91 | |

| 125mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.19-0.21 | 0.049 | 0.92 | |

| 125mm URSA Cavity Batt 32 Light Block (0.31) | 0.21 | 0.050 | 0.92 | |

| 125mm URSA Cavity Batt 32 Light Block (0.45) | 0.22 | 0.051 | 0.92 | |

| 125mm URSA Cavity Batt 32 Medium Block (0.75) | 0.22 | 0.053 | 0.92 | |

| 125mm URSA Cavity Batt 32 Dense Block (1.30) | 0.22 | 0.058 | 0.92 | |

| 150mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.17-0.18 | 0.043 | 0.93 | |

| 150mm URSA Cavity Batt 32 Light Block (0.31) | 0.18 | 0.044 | 0.93 | |

| 150mm URSA Cavity Batt 32 Light Block (0.45) | 0.19 | 0.045 | 0.93 | |

| 150mm URSA Cavity Batt 32 Medium Block (0.75) | 0.19 | 0.046 | 0.93 | |

| 150mm URSA Cavity Batt 32 Dense Block (1.30) | 0.19 | 0.048 | 0.93 | |

| 175mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.15-0.16 | 0.042 | 0.93 | |

| 175mm URSA Cavity Batt 32 Light Block (0.31-0.45) | 0.16 | 0.045 | 0.93 | |

| 175mm URSA Cavity Batt 32 Medium - Dense Block (0.75-1.30) | 0.16-0.17 | 0.047 | 0.93 |

| Description | U-value (W/m²K) | Psi-value (W/mK) | Temp. factor | Download |

|---|---|---|---|---|

| 100mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.23-0.24 | -0.101 | 0.97 | |

| 100mm URSA Cavity Batt 32 Light Block (0.31) | 0.26 | -0.108 | 0.97 | |

| 100mm URSA Cavity Batt 32 Light Block (0.45) | 0.26 | -0.112 | 0.97 | |

| 100mm URSA Cavity Batt 32 Medium Block (0.75) | 0.27 | -0.116 | 0.97 | |

| 100mm URSA Cavity Batt 32 Dense Block (1.30) | 0.27 | -0.118 | 0.97 | |

| 125mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.19-0.21 | -0.092 | 0.97 | |

| 125mm URSA Cavity Batt 32 Light Block (0.31) | 0.21 | -0.098 | 0.97 | |

| 125mm URSA Cavity Batt 32 Light Block (0.45) | 0.22 | -0.102 | 0.97 | |

| 125mm URSA Cavity Batt 32 Medium - Dense Block (0.75-1.30) | 0.22 | -0.103 | 0.97 | |

| 150mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.17-0.18 | -0.086 | 0.98 | |

| 150mm URSA Cavity Batt 32 Light Block (0.31) | 0.18 | -0.091 | 0.98 | |

| 150mm URSA Cavity Batt 32 Light Block (0.45) | 0.19 | -0.094 | 0.98 | |

| 150mm URSA Cavity Batt 32 Medium Block (0.75) | 0.19 | -0.096 | 0.98 | |

| 150mm URSA Cavity Batt 32 Dense Block (1.30) | 0.19 | -0.097 | 0.98 | |

| 175mm URSA Cavity Batt 32 AAC Blocks (0.11-0.19) | 0.15-0.16 | -0.080 | 0.98 | |

| 175mm URSA Cavity Batt 32 Light Block (0.31-0.45) | 0.16 | -0.086 | 0.98 | |

| 175mm URSA Cavity Batt 32 Medium - Dense Block (0.75-1.30) | 0.16-0.17 | -0.087 | 0.98 |

| Description | U-value (W/m²K) | Psi-value (W/mK) | Temp. factor | Download |

|---|---|---|---|---|

| 100mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.23-0.24 | 0.076 | 0.90 | |

| 100mm URSA Cavity Batt 32 Light Block (0.31) | 0.26 | 0.092 | 0.87 | |

| 100mm URSA Cavity Batt 32 Light Block (0.45) | 0.26 | 0.112 | 0.87 | |

| 100mm URSA Cavity Batt 32 Medium Block (0.75) | 0.27 | 0.150 | 0.85 | |

| 100mm URSA Cavity Batt 32 Dense Block (1.30) | 0.27 | 0.214 | 0.81 | |

| 125mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.19-0.21 | 0.073 | 0.90 | |

| 125mm URSA Cavity Batt 32 Light Block (0.31) | 0.21 | 0.091 | 0.88 | |

| 125mm URSA Cavity Batt 32 Light Block (0.45) | 0.22 | 0.112 | 0.88 | |

| 125mm URSA Cavity Batt 32 Medium Block (0.75) | 0.22 | 0.151 | 0.86 | |

| 125mm URSA Cavity Batt 32 Dense Block (1.30) | 0.22 | 0.217 | 0.83 | |

| 150mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.17-0.18 | 0.072 | 0.91 | |

| 150mm URSA Cavity Batt 32 Light Block (0.31) | 0.18 | 0.091 | 0.88 | |

| 150mm URSA Cavity Batt 32 Light Block (0.45) | 0.19 | 0.110 | 0.88 | |

| 150mm URSA Cavity Batt 32 Medium Block (0.75) | 0.19 | 0.152 | 0.86 | |

| 150mm URSA Cavity Batt 32 Dense Block (1.30) | 0.19 | 0.219 | 0.83 | |

| 175mm URSA Cavity Batt 32 AAC Block (0.11) | 0.15 | 0.062 | 0.92 | |

| 175mm URSA Cavity Batt 32 AAC Block (0.15) | 0.15 | 0.067 | 0.91 | |

| 175mm URSA Cavity Batt 32 AAC Block (0.19) | 0.16 | 0.072 | 0.91 | |

| 175mm URSA Cavity Batt 32 Light Block (0.31) | 0.16 | 0.092 | 0.89 | |

| 175mm URSA Cavity Batt 32 Light Block (0.45) | 0.16 | 0.113 | 0.89 | |

| 175mm URSA Cavity Batt 32 Medium Block (0.75) | 0.16 | 0.155 | 0.87 | |

| 175mm URSA Cavity Batt 32 Dense Block (1.30) | 0.17 | 0.222 | 0.84 |

| Description | U-value (W/m²K) | Psi-value (W/mK) | Temp. factor | Download |

|---|---|---|---|---|

| 100mm URSA CAVITY BATT 32 AAC Block (0.11-0.19) | 0.23-0.24 | 0.066 | 0.91 | |

| 100mm URSA Cavity Batt 32 Light Block (0.31) | 0.26 | 0.078 | 0.89 | |

| 100mm URSA CAVITY BATT 32 Light Block (0.45) | 0.26 | 0.093 | 0.89 | |

| 100mm URSA CAVITY BATT 32 Medium Block (0.75) | 0.27 | 0.123 | 0.87 | |

| 100mm URSA CAVITY BATT 32 Dense Block (1.30) | 0.27 | 0.174 | 0.85 | |

| 125mm URSA CAVITY BATT 32 AAC Block (0.11-0.19) | 0.19-0.21 | 0.064 | 0.92 | |

| 125mm URSA Cavity Batt 32 Light Block (0.31) | 0.21 | 0.078 | 0.90 | |

| 125mm URSA CAVITY BATT 32 Light Block (0.45) | 0.22 | 0.093 | 0.90 | |

| 125mm URSA CAVITY BATT 32 Medium Block (0.75) | 0.22 | 0.124 | 0.88 | |

| 125mm URSA CAVITY BATT 32 Dense Block (1.30) | 0.22 | 0.178 | 0.86 | |

| 150mm URSA CAVITY BATT 32 AAC Block (0.11-0.19) | 0.17-0.18 | 0.063 | 0.92 | |

| 150mm URSA Cavity Batt 32 Light Block (0.31) | 0.18 | 0.078 | 0.90 | |

| 150mm URSA CAVITY BATT 32 Light Block (0.45) | 0.19 | 0.086 | 0.90 | |

| 150mm URSA CAVITY BATT 32 Medium Block (0.75) | 0.19 | 0.123 | 0.90 | |

| 150mm URSA CAVITY BATT 32 Dense Block (1.30) | 0.19 | 0.177 | 0.86 | |

| 175mm URSA Cavity Batt 32 AAC Block (0.11). | 0.15 | 0.051 | 0.93 | |

| 175mm URSA Cavity Batt 32 AAC Block (0.15) | 0.15 | 0.057 | 0.92 | |

| 175mm URSA Cavity Batt 32 AAC Block (0.19) | 0.16 | 0.062 | 0.92 | |

| 175mm URSA Cavity Batt 32 Light Block (0.31) | 0.16 | 0.077 | 0.91 | |

| 175mm URSA Cavity Batt 32 Light Block (0.45) | 0.16 | 0.094 | 0.91 | |

| 175mm URSA Cavity Batt 32 Medium Block (0.75) | 0.16 | 0.128 | 0.89 | |

| 175mm URSA Cavity Batt 32 Dense Block (1.30) | 0.17 | 0.182 | 0.86 |

| Description | U-value (W/m²K) | Psi-value (W/mK) | Temp. factor | Download |

|---|---|---|---|---|

| 100mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.23-0.24 | 0.067 | 0.91 | |

| 100mm URSA Cavity Batt 32 Light Block (0.31-0.45) | 0.26 | 0.067 | 0.91 | |

| 100mm URSA Cavity Batt 32 Medium Block (0.75) | 0.27 | 0.069 | 0.91 | |

| 100mm URSA Cavity Batt 32 Dense Block (1.30) | 0.27 | 0.071 | 0.92 | |

| 125mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.19-0.21 | 0.071 | 0.91 | |

| 125mm URSA Cavity Batt 32 Light Block (0.31) | 0.21 | 0.072 | 0.91 | |

| 125mm URSA Cavity Batt 32 Light Block (0.45) | 0.22 | 0.074 | 0.91 | |

| 125mm URSA Cavity Batt 32 Medium Block (0.75) | 0.22 | 0.077 | 0.92 | |

| 125mm URSA Cavity Batt 32 Dense Block (1.30) | 0.22 | 0.080 | 0.92 | |

| 150mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.17-0.18 | 0.074 | 0.91 | |

| 150mm URSA Cavity Batt 32 Light Block (0.31) | 0.18 | 0.076 | 0.92 | |

| 150mm URSA Cavity Batt 32 Light Block (0.45) | 0.19 | 0.078 | 0.92 | |

| 150mm URSA Cavity Batt 32 Medium Block (0.75) | 0.19 | 0.081 | 0.92 | |

| 150mm URSA Cavity Batt 32 Dense Block (1.30) | 0.19 | 0.083 | 0.92 | |

| 175mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.15-0.16 | 0.078 | 0.91 | |

| 175mm URSA Cavity Batt 32 Light Block (0.31-0.45) | 0.16 | 0.082 | 0.91 | |

| 175mm URSA Cavity Batt 32 Medium Block (0.75) | 0.16 | 0.086 | 0.92 | |

| 175mm URSA Cavity Batt 32 Dense Block (1.30) | 0.17 | 0.089 | 0.92 |

| Description | U-value (W/m²K) | Psi-value (W/mK) | Temp. factor | Download |

|---|---|---|---|---|

| 100mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.23-0.24 | 0.086 | 0.91 | |

| 100mm URSA Cavity Batt 32 Light Block (0.31) | 0.25 | 0.086 | 0.91 | |

| 100mm URSA Cavity Batt 32 Light Block (0.45) | 0.26 | 0.088 | 0.91 | |

| 100mm URSA Cavity Batt 32 Medium Block (0.75) | 0.27 | 0.090 | 0.91 | |

| 100mm URSA Cavity Batt 32 Dense Block (1.30) | 0.27 | 0.092 | 0.91 | |

| 125mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.19-0.21 | 0.090 | 0.91 | |

| 125mm URSA Cavity Batt 32 Light Block (0.31) | 0.21 | 0.092 | 0.91 | |

| 125mm URSA Cavity Batt 32 Light Block (0.45) | 0.22 | 0.094 | 0.91 | |

| 125mm URSA Cavity Batt 32 Medium Block (0.75) | 0.22 | 0.097 | 0.91 | |

| 125mm URSA Cavity Batt 32 Dense Block (1.30) | 0.22 | 0.099 | 0.92 | |

| 150mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.17-0.18 | 0.092 | 0.91 | |

| 150mm URSA Cavity Batt 32 Light Block (0.31) | 0.18 | 0.095 | 0.92 | |

| 150mm URSA Cavity Batt 32 Light Block (0.45) | 0.19 | 0.097 | 0.92 | |

| 150mm URSA Cavity Batt 32 Medium Block (0.75) | 0.19 | 0.100 | 0.92 | |

| 175mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.15-0.16 | 0.078 | 0.91 | |

| 175mm URSA Cavity Batt 32 Light Block (0.31-0.45) | 0.16 | 0.099 | 0.92 | |

| 175mm URSA Cavity Batt 32 Medium Block (0.75) | 0.16 | 0.103 | 0.92 | |

| 175mm URSA Cavity Batt 32 Dense Block (1.30) | 0.17 | 0.107 | 0.92 |

| Description | U-value (W/m²K) | Psi-value (W/mK) | Temp. factor | Download |

|---|---|---|---|---|

| 100mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.23-0.24 | 0.002 | 0.96 | |

| 100mm URSA Cavity Batt 32 Light Block (0.31-0.45) | 0.26 | 0.002 | 0.96 | |

| 100mm URSA Cavity Batt 32 Medium Block (0.75) | 0.27 | 0.003 | 0.96 | |

| 100mm URSA Cavity Batt 32 Dense Block (1.30) | 0.27 | 0.003 | 0.96 | |

| 125mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.19-0.21 | 0.002 | 0.96 | |

| 125mm URSA Cavity Batt 32 Light Block (0.31-0.45) | 0.21-0.22 | 0.002 | 0.97 | |

| 125mm URSA Cavity Batt 32 Medium Block (0.75) | 0.22 | 0.003 | 0.97 | |

| 125mm URSA Cavity Batt 32 Dense Block (1.30) | 0.22 | 0.003 | 0.96 | |

| 150mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.17-0.18 | 0.002 | 0.97 | |

| 150mm URSA Cavity Batt 32 Light Block (0.31-0.45) | 0.18-0.19 | 0.002 | 0.97 | |

| 150mm URSA Cavity Batt 32 Medium Block (0.75) | 0.19 | 0.003 | 0.97 | |

| 150mm URSA Cavity Batt 32 Dense Block (1.30) | 0.19 | 0.003 | 0.97 | |

| 175mm URSA Cavity Batt 32 AAC Blocks (0.11-0.19). Light - medium blocks (0.31-0.75) | 0.15-0.16 | 0.001 | 0.97 | |

| 175mm URSA Cavity Batt 32 Dense Block (1.30) | 0.17 | 0.002 | 0.97 |

| Description | U-value (W/m²K) | Psi-value (W/mK) | Temp. factor | Download |

|---|---|---|---|---|

| 100mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.23-0.24 | 0.011 | 0.96 | |

| 100mm URSA Cavity Batt 32 Light Block (0.31-0.45) | 0.26 | 0.009 | 0.96 | |

| 100mm URSA Cavity Batt 32 Medium Block (0.75) | 0.27 | 0.008 | 0.95 | |

| 100mm URSA Cavity Batt 32 Dense Block (1.30) | 0.27 | 0.007 | 0.95 | |

| 125mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.19-0.21 | 0.008 | 0.97 | |

| 125mm URSA Cavity Batt 32 Light Block (0.31) | 0.21 | 0.007 | 0.96 | |

| 125mm URSA Cavity Batt 32 Light Block (0.45) | 0.22 | 0.006 | 0.96 | |

| 125mm URSA Cavity Batt 32 Medium-Dense Block (0.75-1.30) | 0.22 | 0.005 | 0.96 | |

| 150mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.17-0.18 | 0.006 | 0.97 | |

| 150mm URSA Cavity Batt 32 Light Block (0.31) | 0.18 | 0.005 | 0.97 | |

| 150mm URSA Cavity Batt 32 Light Block (0.45) | 0.19 | 0.004 | 0.97 | |

| 150mm URSA Cavity Batt 32 Medium Block (0.75) | 0.19 | 0.004 | 0.97 | |

| 150mm URSA Cavity Batt 32 Dense Block (1.30) | 0.19 | 0.003 | 0.97 | |

| 175mm URSA Cavity Batt 32 AAC Blocks (0.11-0.19) | 0.15-0.16 | 0.005 | 0.98 | |

| 175mm URSA Cavity Batt 32 Light Block (0.31) | 0.16 | 0.004 | 0.97 | |

| 175mm URSA Cavity Batt 32 Light-Dense Block (0.45-1.30) | 0.16-0.17 | 0.003 | 0.97 |

| Description | U-value (W/m²K) | Psi-value (W/mK) | Temp. factor | Download |

|---|---|---|---|---|

| 100mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.23-0.24 | 0.015 | 0.93 | |

| 100mm URSA Cavity Batt 32 Light Block (0.31-0.45) | 0.26 | 0.014 | 0.92 | |

| 100mm URSA Cavity Batt 32 Medium-Dense Block (0.75-1.30) | 0.27 | 0.013 | 0.92 | |

| 125mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.19-0.21 | 0.016 | 0.93 | |

| 125mm URSA Cavity Batt 32 Light Block (0.31) | 0.21 | 0.014 | 0.93 | |

| 125mm URSA Cavity Batt 32 Light Block (0.45) | 0.22 | 0.013 | 0.93 | |

| 125mm URSA Cavity Batt 32 Medium-Dense Block (0.75-1.30) | 0.22 | 0.013 | 0.93 | |

| 150mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.17-0.18 | 0.020 | 0.91 | |

| 150mm URSA Cavity Batt 32 Light Block (0.31-0.45) | 0.18-0.19 | 0.020 | 0.93 | |

| 150mm URSA Cavity Batt 32 Medium-Dense Block (0.75-1.30) | 0.19 | 0.019 | 0.91 | |

| 175mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.15-0.16 | 0.022 | 0.93 | |

| 175mm URSA Cavity Batt 32 Light-Dense Block (0.31-1.30) | 0.16-0.17 | 0.022 | 0.93 |

| Description | U-value (W/m²K) | Psi-value (W/mK) | Temp. factor | Download |

|---|---|---|---|---|

| 100mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.23-0.24 | 0.015 | 0.92 | |

| 100mm URSA Cavity Batt 32 Light Block (0.31-0.45) | 0.26 | 0.014 | 0.92 | |

| 100mm URSA Cavity Batt 32 Medium-Dense Block (0.75-1.30) | 0.27 | 0.014 | 0.92 | |

| 125mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.19-0.21 | 0.017 | 0.92 | |

| 125mm URSA Cavity Batt 32 Light Block (0.31-0.45) | 0.21-0.22 | 0.017 | 0.92 | |

| 125mm URSA Cavity Batt 32 Medium-Dense Block (0.75-1.30) | 0.22 | 0.016 | 0.92 | |

| 150mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.17-0.18 | 0.022 | 0.92 | |

| 150mm URSA Cavity Batt 32 Light Block (0.31) | 0.18 | 0.020 | 0.92 | |

| 150mm URSA Cavity Batt 32 Light Block (0.31-0.45) | 0.18-0.19 | 0.019 | 0.92 | |

| 150mm URSA Cavity Batt 32 Medium-Dense Block (0.75-1.30) | 0.19 | 0.019 | 0.92 | |

| 175mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.15-0.16 | 0.022 | 0.87 | |

| 175mm URSA Cavity Batt 32 Light-Medium Block (0.31-0.75) | 0.16 | 0.020 | 0.87 | |

| 175mm URSA Cavity Batt 32 Dense Block (1.30) | 0.16 | 0.19 | 0.87 |

| Description | U-value (W/m²K) | Psi-value (W/mK) | Temp. factor | Download |

|---|---|---|---|---|

| 100mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.23-0.24 | 0.065 | 0.94 | |

| 100mm URSA Cavity Batt 32 Light Block (0.31) | 0.26 | 0.071 | 0.92 | |

| 100mm URSA Cavity Batt 32 Light Block (0.45) | 0.26 | 0.081 | 0.92 | |

| 100mm URSA Cavity Batt 32 Medium Block (0.75) | 0.27 | 0.110 | 0.91 | |

| 100mm URSA Cavity Batt 32 Dense Block (1.30) | 0.27 | 0.121 | 0.90 | |

| 125mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.19-0.21 | 0.069 | 0.94 | |

| 125mm URSA Cavity Batt 32 Light Block (0.31) | 0.21 | 0.085 | 0.93 | |

| 125mm URSA Cavity Batt 32 Light Block (0.45) | 0.22 | 0.095 | 0.93 | |

| 125mm URSA Cavity Batt 32 Medium Block (0.75) | 0.22 | 0.124 | 0.92 | |

| 125mm URSA Cavity Batt 32 Dense Block (1.30) | 0.22 | 0.173 | 0.90 | |

| 150mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.17-0.18 | 0.066 | 0.94 | |

| 150mm URSA Cavity Batt 32 Light Block (0.31) | 0.18 | 0.083 | 0.93 | |

| 150mm URSA Cavity Batt 32 Light Block (0.45) | 0.19 | 0.084 | 0.93 | |

| 150mm URSA Cavity Batt 32 Medium Block (0.75) | 0.19 | 0.120 | 0.92 | |

| 150mm URSA Cavity Batt 32 Dense Block (1.30) | 0.19 | 0.173 | 0.90 | |

| 175mm URSA Cavity Batt 32 AAC Blocks (0.11) | 0.15 | 0.080 | 0.95 | |

| 175mm URSA Cavity Batt 32 AAC Block (0.15) | 0.15 | 0.085 | 0.95 | |

| 175mm URSA Cavity Batt 32 AAC Block (0.19) | 0.16 | 0.091 | 0.95 | |

| 175mm URSA Cavity Batt 32 Light Block (0.31) | 0.16 | 0.104 | 0.93 | |

| 175mm URSA Cavity Batt 32 Light Block (0.45) | 0.16 | 0.116 | 0.93 | |

| 175mm URSA Cavity Batt 32 Medium Block (0.75) | 0.16 | 0.144 | 0.92 | |

| 175mm URSA Cavity Batt 32 Dense Block (1.30) | 0.17 | 0.175 | 0.92 |

| Description | U-value (W/m²K) | Psi-value (W/mK) | Temp. factor | Download |

|---|---|---|---|---|

| 100mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.23-0.24 | 0.060 | 0.94 | |

| 100mm URSA Cavity Batt 32 Light Block (0.31) | 0.26 | 0.075 | 0.92 | |

| 100mm URSA Cavity Batt 32 Light Block (0.45) | 0.26 | 0.089 | 0.92 | |

| 100mm URSA Cavity Batt 32 Medium Block (0.75) | 0.27 | 0.119 | 0.91 | |

| 100mm URSA Cavity Batt 32 Dense Block (1.30) | 0.27 | 0.170 | 0.89 | |

| 125mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.19-0.21 | 0.062 | 0.94 | |

| 125mm URSA Cavity Batt 32 Light Block (0.31) | 0.21 | 0.078 | 0.93 | |

| 125mm URSA Cavity Batt 32 Light Block (0.45) | 0.22 | 0.085 | 0.92 | |

| 125mm URSA Cavity Batt 32 Medium Block (0.75) | 0.22 | 0.129 | 0.91 | |

| 125mm URSA Cavity Batt 32 Dense Block (1.30) | 0.22 | 0.178 | 0.90 | |

| 150mm URSA Cavity Batt 32 AAC Block (0.11-0.19) | 0.17-0.18 | 0.062 | 0.94 | |

| 150mm URSA Cavity Batt 32 Light Block (0.31) | 0.18 | 0.079 | 0.93 | |

| 150mm URSA Cavity Batt 32 Light Block (0.45) | 0.19 | 0.091 | 0.93 | |

| 150mm URSA Cavity Batt 32 Medium Block (0.75) | 0.19 | 0.131 | 0.92 | |

| 150mm URSA Cavity Batt 32 Dense Block (1.30) | 0.19 | 0.181 | 0.90 | |

| 175mm URSA Cavity Batt 32 AAC Blocks (0.11) | 0.15 | 0.049 | 0.95 | |

| 175mm URSA Cavity Batt 32 AAC Block (0.15) | 0.15 | 0.055 | 0.95 | |

| 175mm URSA Cavity Batt 32 AAC Block (0.19) | 0.16 | 0.062 | 0.95 | |

| 175mm URSA Cavity Batt 32 Light Block (0.31) | 0.16 | 0.077 | 0.93 | |

| 175mm URSA Cavity Batt 32 Light Block (0.45) | 0.16 | 0.092 | 0.93 | |

| 175mm URSA Cavity Batt 32 Medium Block (0.75) | 0.16 | 0.126 | 0.92 | |

| 175mm URSA Cavity Batt 32 Dense Block (1.30) | 0.17 | 0.172 | 0.91 |