Rainscreen Cladding

URSA WALLTEC BLACK and URSAPAN BLACK slabs are BBA approved for use behind rainscreen cladding systems, both new build and refurbishment. The slabs have a black glass fleece facing so they can be used in open joint cladding systems without being seen. URSAPAN slabs have a plain glass fleece facing.

URSA WALLTEC BLACK - thermal conductivity 0.032 W/mK.

URSAPAN BLACK - thermal conductivity 0.035 W/mK.

BBA Certificate 20/5832.

URSAPAN - thermal conductivity 0.035 W/mK.

Design

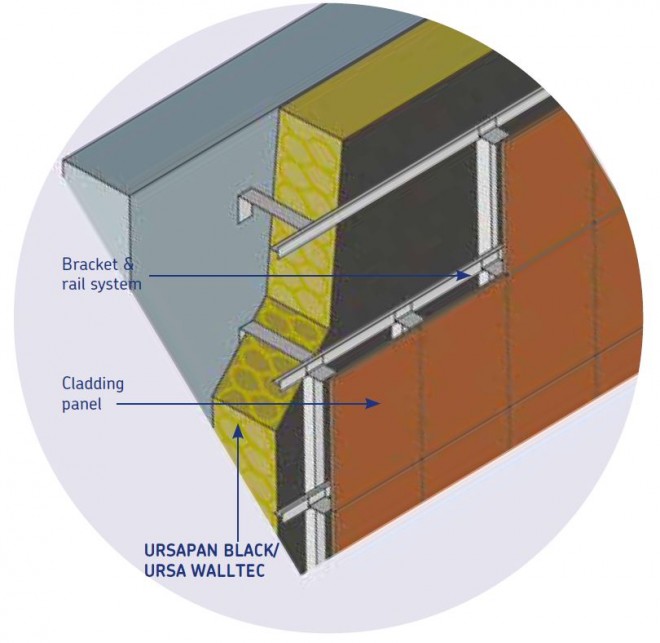

Rainscreen cladding is a lightweight, non-load bearing system attached to the outside of a building using a bracket and rail system. The cladding system provides protection from wind and rain, improves the thermal performance and limits solar gains. A ventilated void, typically 50mm, behind the cladding keeping the system dry.

Rainscreen systems are also available that use a traditional brick (or block) external leaf and nominal 50mm clear cavity.

The class leading performance URSA WALLTEC BLACK, thermal conductivity 0.032 W/mK, provides a continuous envelope of insulation around the building. Alternatively URSAPAN BLACK or URSAPAN, thermal conductivity 0.035 W/mK, may be used. The ventilated cavity and external insulation protect the building from summer overheating whilst during the heating season advantage can be taken of the high thermal mass of concrete framed buildings.

Larger slab size, 1350mm x 600mm, means 12.5% fewer boards to install and 12.5% fewer fixings are required.

URSA WALLTEC BLACK, URSAPAN BLACK and URSAPAN are totally non-combustible, Euroclass A1, so do not add any fire load to the building or prejudice the overall fire performance of the wall. The presence of the ventilated cavity behind the cladding system means that cavity barriers as required to prevent the spread of fire and/or smoke. It is recommended that horizontal cavity barriers are installed at every compartment floor level, at roof level and if required vertical barrier to further sub-divide the cavity at compartment walls. See Approved Document B (England & Wales) and the Fire Section of the Technical Handbooks (Scotland). Similarly all openings should be correctly fire stopped to prevent a fire from inside the building being able to break into the cavity.

These design recommendations show compliance with all relevant sections of the Building Regulations and NHBC Standards.

It should be noted that the Approved Document B for England & Wales requires insulation products in high rise (11m or more) cladding systems be of ‘limited combustibility’ or better. In Scotland the insulation should be ‘non-combustible’ in buildings above 11m in height.

Installation

Rainscreen Cladding

URSA WALLTEC BLACK/URSAPAN BLACK/URSAPAN may be fixed to masonry, timber frame and light metal frame walls. The slabs are mechanically fixed to the wall structure between the brackets used to support the cladding system. The usual procedure for construction is;

- Timber and metal stud framed walls should include a suitable air and vapour control layer on the inner surface behind the plasterboard. Timber frame walls should also include a breather membrane external to the sheathing.

- The cladding system brackets are fixed to the main structural wall in accordance with the manufacturer’s instructions.

- Fix the URSA WALLTEC BLACK/URSAPAN BLACK/URSAPAN slabs to the wall in a staggered pattern, black face outermost. Installation may start below DPC level to help insulate the edge of the floor slab. The slabs may be fitted in either landscape or portrait format. Ensure all joints are tightly butted together and that the slabs are cut accurately and tightly around the brackets ensuring that there are no gaps. Leaving the slabs cut slightly oversize ensures that the fibres will ‘knit’ together. The slabs cut easily with the use of a sharp knife.

- The URSA WALLTEC BLACK/URSAPAN BLACK/URSAPAN slabs are mechanically fixed to the wall using suitable insulation retaining fixings (with a minimum head diameter of 70mm) depending upon the substrate. A typical fixing pattern is three fixings along the centre line of the slab – the central fixing in each slab must be metal rather than plastic. Alternatively use a plastic fixing at the corner of each slab with a with a metal fixing at the centre. Do not overdrive the fixings.

- URSA WALLTEC BLACK/URSAPAN BLACK/URSAPAN slabs may be installed in two or more layers if a particularly low U-value is required. Install the first layer of slabs with one mechanical fixing per board. Ensure the position of this fixing does not interfere with the final fixing pattern for the slabs. Install the second layer of slabs, with staggered joints, and install the final fixings as above.

- Ensure that cavity barriers are installed in accordance with the Building Regulations. In high rise this would include at every compartment floor level and at the top of the cavity. Ensure external openings are correctly sealed also.

- URSA WALLTEC BLACK/URSAPAN BLACK/URSAPAN is robust enough to be left exposed and will withstand short term, intermittent wetting. If prolonged bad weather (rain, snow, high wind, freezing conditions) is predicted fit only sufficient slabs that can be covered and protected by the cladding on the same day; otherwise provide temporary weather protection. If the slabs get wet they should be allowed to dry naturally – they will retain their original thermal performance. Damaged slabs should be replaced.

- Once the insulation is fitted the external cladding work may proceed in accordance with the manufacturer’s instructions.

Smugglers Way, Wandsworth case study and typcial install here.

This link shows a typical rainscreen cladding installation.

This link shows a more detailed installation including the principles of rainscreen cladding..

Note these are from URSA in Europe - UK product names and fixing details will be different (see above).

URSA WALLTEC BLACK U-values

Rainscreen Cladding

| URSA WALLTEC BLACK (mm) |

U-value (W/m²K) 150mm light steel stud |

U-value (W/m²K) 150mm dense masonry |

| 100 | 0.21 | 0.37 |

| 120 | 0.19 | 0.33 |

| 140 | 0.18 | 0.30 |

| 160 | 0.17 | 0.28 |

| 180 | 0.16 | 0.26 |

| 200 | 0.15 | 0.24 |

| 220 | 0.14 | 0.23 |

Brick Outer Leaf Cladding

URSA WALLTEC BLACK/URSAPAN BLACK/URSAPAN may be fixed to masonry, timber frame and light metal frame walls. The slabs are mechanically fixed to the wall structure behind the restraint channel used to tie the brick or block outer leaf to the structure. The usual procedure for construction is;

- Timber and metal stud framed walls should include a suitable air and vapour control layer on the inner surface behind the plasterboard. Timber frame walls should also include a breather membrane external to the sheathing.

- Fix the URSA WALLTEC BLACK/URSAPAN BLACK/URSAPAN slabs horizontally in a staggered, brick bond, pattern with the black face outermost. Installation may start below DPC level to help insulate the edge of the floor slab. Ensure all joints are tightly butted together and that the slabs are cut accurately around openings and penetrations. The slabs cut easily with the use of a sharp knife.

- To assist in their installation the URSA WALLTEC BLACK/URSAPAN BLACK/URSAPAN slabs may be initially fixed to the wall using suitable insulation retaining fixings (with a minimum head diameter of 70mm). One fixing per slab (or part slab) is normally sufficient.

- URSA WALLTEC BLACK/URSAPAN BLACK/URSAPAN slabs may be installed in two or more layers if a particularly low U-value is required. Install the first layer of slabs with one mechanical fixing per board. Ensure the position of this fixing does not interfere with the final fixing pattern for the slabs. Install the second layer of slabs, with staggered joints, and install the final fixings as above.

- Ensure that cavity barriers are installed in accordance with the Building Regulations. In high rise this would include at every compartment floor level and at the top of the cavity. Ensure external openings are correctly sealed also.

- Once the insulation is fitted install the channel restraint system, normally at 600mm horizontal centres, using suitable bolts or screws depending upon substrate. Ensure the fixings give a positive stand-off or incorporate a compression sleeve. Follow the manufacturer's instructions.

- Alternatively, the channels and associated compression sleeves (to suit insulation thickness) and screw fixings may be installed before the insulation. The channels must be accurately set out at 600mm horizontal centres. Fit the insulation slabs vertically, slotting them between the channels and then add 2 mechanical fixings on the centre line and 200mm-250mm from each end of the slab.

- The brick or block outer leaf is built in accordance with good practice using ties slotted into the restraint channel.

- Alternatively the insulation slabs may be installed vertically between cranked wall ties with suitable retaining collars. If necessary slit the slab edges with a knife to enable them to fit neatly around the wall ties. There is no need for separate mechanical fixings.

- URSA WALLTEC BLACK/URSAPAN BLACK/URSAPAN is robust enough to be left exposed and will withstand short term, intermittent wetting. If prolonged bad weather (rain, snow, high wind, freezing conditions) is predicted fit only sufficient slabs that can be covered and protected by the cladding on the same day; otherwise provide temporary weather protection. If the slabs get wet they should be allowed to dry naturally – they will retain their original thermal performance. Damaged slabs should be replaced.

URSA WALLTEC BLACK 32 U-values

Brick Outer Leaf

| URSA WALLTEC BLACK (mm) |

U-value (W/m²K) 150mm light steel stud |

U-value (W/m²K) 150mm dense masonry |

| 100 | 0.16 | 0.28 |

| 120 | 0.14 | 0.24 |

| 140 | 0.13 | 0.21 |

| 160 | 0.12 | 0.19 |

| 180 | 0.12 | 0.17 |

| 200 | 0.11 | 0.15 |

| 220 | 0.10 | 0.15 |

For further information and more U-values see our technical brochure in the Documents section.

We can also undertake 3D thermal modelling to accurately show the effect of the brackets on the overall U-value in rainscreen cladding systems. Please contact URSA Technical Services.