Rafter Level Roof Insulation

URSA FRAMETEC, URSA TIMBER FRAME SLAB and URSA HOMETEC ROLL are suitable for use at rafter level for habitable or room in roof construction (warm roof space).

URSA FRAMETEC 32 - thermal conductivity 0.032 W/mK.

URSA FRAMETEC SLAB 32 - thermal conductivity 0.032 W/mK.

URSA HOMETEC ROLL 32 - thermal conductivity 0.032 W/mK.

URSA FRAMETEC 35 - thermal conductivity 0.035 W/mK.

URSA HOMETEC ROLL 35 - thermal conductivity 0.035 W/mK.

Design

URSA FRAMETEC/FRAMETEC SLABS and URSA HOMETEC ROLLS are suitable for both ventilated and unventilated warm roof spaces at rafter level.

To minimise the condensation risk a vapour control layer is required when insulating between the rafters, this can either be a polythene sheet (minimum 500g) or a foil-backed plasterboard. The use of the vapour control layer also creates an air barrier that helps to improve the air tightness of the building and so limit air infiltration. The type of roofing underlay should be carefully considered. Breathable membranes (Type LR) may not require roof space ventilation provided they are covered by BBA certification. More traditional bitumen or polythene based membranes (Type HR) require provision for eaves to ridge ventilation.

The plasterboard ceiling should be sealed at the junction with walls with plaster, adhesive or flexible sealant and around service penetrations using a flexible sealant.

Recessed lighting should be in a sufficiently large enclosure to ensure continuity of the insulation whilst still allowing heat to dissipate from the lamp. The fixture should be sealed to maintain a vapour tight ceiling and prevent unwanted air leakage.

Installation

Warm Roof Construction

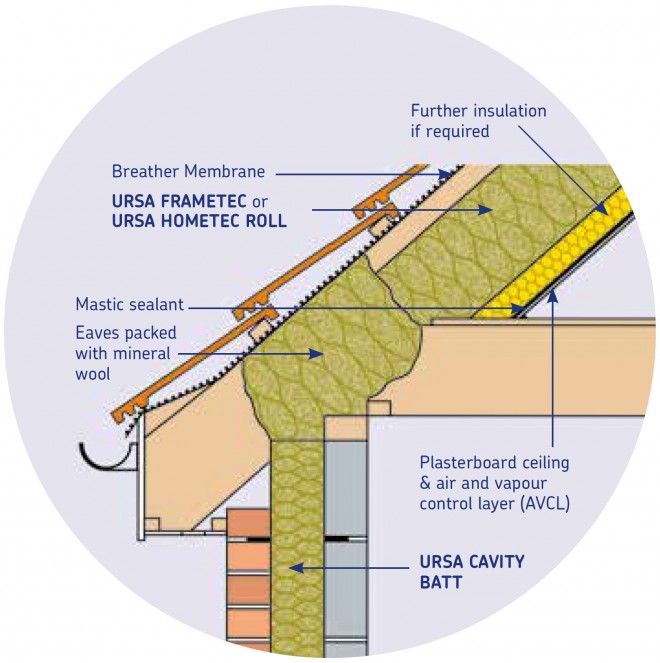

URSA FRAMETEC/FRAMETEC SLABS or URSA HOMETEC ROLLS are designed to fit between the roof timbers at rafter level creating a warm roof space. The usual procedure for construction is;

- Install the warm roof, over rafter, insulation and secure using counterbattens in accordance with the manufacturer's instructions and complete the tiling, battening and felting using a BBA approved LR (breather) type underlay.

- Once the roof is watertight and working from the inside fit the URSA FRAMETEC or URSA HOMETEC ROLL between the rafters. Ensure the depth of the rafters is fully filled and there are no gaps between the rafters and between sections of insulation.

- Continue the URSA FRAMETEC or URSA HOMETEC ROLL into the dwarf (knee) walls to maintain continuity of insulation.

- An air and vapour control layer (AVCL) is recommedned with this form of warm roof construction especially in high humidity applications such as swimming poolss, laundries, commercial kitchens etc.

- Ensure that the insulation continues over the wall plate to maintain continuity with the wall insulation.

- Ensure that any penetrations through the ceiling, especially if formed by following trades, are correctly sealed to ensure an air and vapour tight ceiling.

- The plasterboard ceiling, incorporating an air and vapour control layer (AVCL) is installed, ensuring the AVCL is correctly detailed and sealed.

Cold Roof Construction

URSA FRAMETEC/FRAMETEC SLABS or URSA HOMETEC ROLLS are designed to fit between the roof timbers at rafter level creating a warm roof space. The usual procedure for construction is;

- The roof trusses, sarking membrane (Type LR or Type HR), sarking boards (if applicable), tiling battens and tiles are all installed in the normal way in accordance with good practice and BS 5534.

- When using Type HR membranes there must be provision for a ventilated airspace from the eaves to the ridge. Proprietary eaves ventilators should be used to maintain a clear path from the eaves vents into the roof void. Type LR membranes may not require ventilation of the roof space provided they are covered by BBA certification.

- Fit the URSA FRAMETEC or URSA HOMETEC ROLL between the rafters ensuring that there are no gaps between the rafters and between sections of insulation.

- Ensure there is sufficient drape in the sarking membrane to maintain drainage. If the rafter void is fully filled and the membrane is in contact with the insulation counter battens must be used to ensure correct drainage. Also check with the membrane manufacturer for suitability in fully supported applications.

- Continue the URSA FRAMETEC or URSA HOMETEC ROLL into the dwarf (knee) walls to maintain continuity of insulation.

- If required additional insulation may be added under the rafters to both enhance the thermal performance of the roof and to mask the thermal bridge effect of the rafters.

- The plasterboard ceiling, incorporating an air and vapour control layer (AVCL) is installed, ensuring the AVCL is correctly detailed and sealed.

- Ensure that the insulation continues over the wall plate to maintain continuity with the wall insulation.

- Ensure that any penetrations through the ceiling, especially if formed by following trades, are correctly sealed to ensure an air and vapour tight ceiling.

URSA FRAMETEC 32/HOMETEC ROLL 32 U-values

| URSA FRAMETEC 32/HOMETEC ROLL 32 |

U-value (W/m²K) |

| 140mm FRAMETEC & 50mm PUR | 0.16 |

| 140mm FRAMETEC & 60mm PUR | 0.15 |

| 200mm HOMETEC & 50mm PUR | 0.13 |

| 200mm HOMETEC & 60mm PUR | 0.12 |

For further information and more U-values see our technical brochure in the Documents section. Alternatively please contact URSA Technical Department.