Party Wall Thermal Bypass Solutions

URSA PARTY WALL ROLLS, URSA CAVITY BATTS, URSA ACOUSTIC ROLLS and URSA FRAMETEC are suitable for masonry and timber frame party cavity walls to prevent party wall thermal bypass.

URSA CAVITY BATTS and URSA PARTY WALL ROLL are suitable for use in fully filling the party wall cavity to prevent party wall thermal bypass in masonry walls.

URSA ACOUSTIC ROLL and URSA FRAMETEC are suitable for use in fully filling the inter stud and inter frame cavities to prevent party wall thermal bypass in timber framed walls.

URSA FRAMETEC SLAB 35, URSA ACOUSTIC ROLL and URSA HOMETEC ROLL 35 are suitable for use in fully filling the inter stud and inter frame cavities to prevent party wall thermal bypass in light steel framed walls.

URSA CAVITY BATT 35 - thermal conductivity 0.035 W/mK.

Density 22 kg/m³.

URSA CAVITY BATT 32 - thermal conductivity 0.032 W/mK.

Density 32 kg/m³.

URSA PARTY WALL ROLL - thermal conductivity 0.035 W/mK.

Density 22 kg/m³.

URSA ACOUSTIC ROLL - thermal conductivity 0.035 W/mK.

Density 22 kg/m³.

URSA HOMETEC ROLL 35 - thermal conductivity 0.035 W/mK.

Density 22 kg/m³.

URSA FRAMETEC 35 & FRAMETEC SLAB 35 - thermal conductivity 0.035 W/mK.

Density 22 kg/m³.

Design

Traditionally the heat loss through separating/party cavity walls in semi detached and terraced properties was assumed to be zero as there is no temperature differential across the wall. Studies have shown however that air movement within this cavity (with further infiltration from the front and rear external cavity walls) means the separating wall can have an equivalent U-value as high as 0.70 W/m²K. The Building Regulations now recognise the importance of the party wall thermal bypass and measures must be taken to reduce its effect. The studies have identified two important measures;

- Fully filling the cavity with glass wool, with a minimum density of 18 kg/m³.

- Installing adequate edge sealing at all exposed edges and contiguous with the insulation in adjacent elements.

Further more detailed information is available from the Mineral Wool Manufacturers Association (MIMA) in their document 'Preventing Thermal Bypassess in Party Separating Walls'.

For optimum performance the party cavity wall insulation and the edge sealing must be contiguous. These measures will reduce the heat flow through, across and along the separating wall and reduce air movement into and within the wall. Done correctly these will reduce the U-value of the wall to zero. Effective edge sealing alone will only reduce the U-value to 0.20 W/m²K.

Masonry cavity and timber frame separating walls must provide suitable sound insulation between dwellings as outlined in Approved Document E of the Building Regulations (Section 5 in Scotland). Suitable details have been used successfully for many years; adding further layers of insulation into the walls must not degrade this performance. Extensive testing has been undertaken to show that the use of glass mineral wool fully filling any cavities does not degrade the performance.

The above products are covered by a range of acoustic solutions under the Robust Details for parged and unparged masonry walls and timber framed walls. See below for more details.

URSA FRAMETEC, URSA ACOUSTIC ROLL, URSA CAVITY BATT and URSA PARTY WALL ROLL are all classed as non-combustible and will not prejudice the fire resistance properties of the wall.

Installation

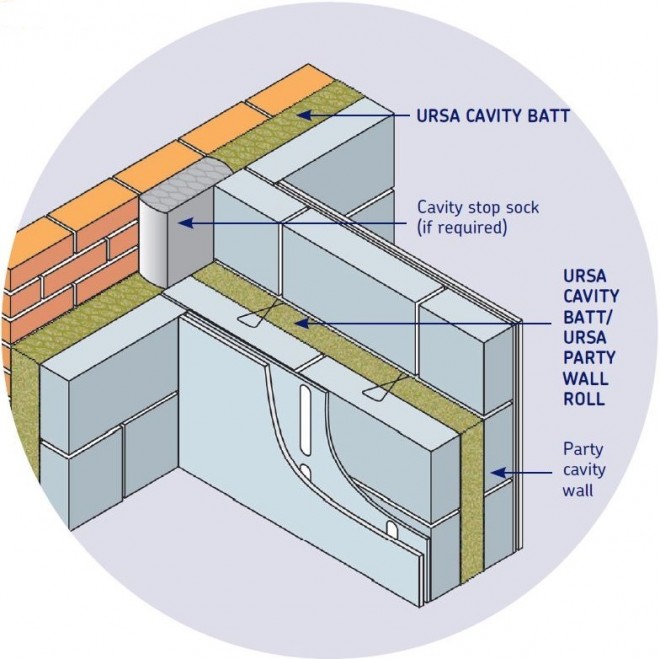

Masonry Party Cavity Wall

URSA CAVITY BATT or URSA PARTY WALL ROLL is installed in the party wall as the wall is built. The usual procedure for construction is;

- The party wall may be built leading with either leaf; a minimum 75mm cavity must be maintained.

- Install the first row of URSA CAVITY BATTS/PARTY WALL ROLL, cut to size if necessary, against the leading leaf. The batts/slabs may start below DPC to ensure continuity with the floor insulation and to minimise thermal bridging.

- Raise the next leaf to the level of the URSA CAVITY BATTS/PARTY WALL ROLL.

- Raise the leading leaf to the next row of wall ties and clean any excess mortar before installing the next row of URSA CAVITY BATTS/PARTY WALL ROLL..

- Subsequent rows of slabs/rolls should be installed with vertical joints staggered i.e in a brick bond pattern.

- As work proceeds ensure that the top edge of the slabs in kept clean and free from mortar droppings.

- Cut sections of slab/roll may be required at corners and at junctions. It is essential that these are cut accurately to fill the space they are intended for.

- Ensure that partially completed walls are protected from inclement weather and at the end of the day's work

Timber Frame Party Cavity Wall

URSA FRAMETEC is installed in both leaves of the separating stud wall and URSA Acoustic Roll is used in the cavity between the two leaves. The usual procedure for construction is;

- Fit the timber frame walls in the normal manner and in accordance with the manufacturer's instructions ensuring a minimum of 240mm between the inner faces of the wall linings and 50mm separation between the studs of each leaf. If plywood sheathing is used ensure a 50mm (minimum) gap is still maintained.

- Install URSA ACOUSTIC ROLL between the frames. High tack spray adhesive may be used to secure the ACOUSTIC ROLL to one of the leaves when using plywood sheathing. Ensure the insulation thickness fully fills the cavity with allowance made for on-site tolerances.

- Install URSA FRAMETEC between both frames fully filling the depth of the studs.

- Install vertical cavity barriers (for acoustic, thermal and fire performance) ensuring that they are contiguous with the party wall insulation.

- Ensure that partially completed walls are protected from inclement weather and at the end of the day's work.

- The plasterboard is installed on both faces of the party wall in the normal manner.

Light Steel Frame Party Cavity Wall

URSA FRAMETEC SLAB 35, URSA ACOUSTIC ROLL or URSA HOMETEC ROLL 35 is installed in both leaves of the separating stud wall and in the cavity between the two leaves.

Robust Details

This range of URSA products is approved for use in a number of Robust Details for masonry and timber frame walls. Check the Robust Details handbook (link below) for the exact specification in each detail.

*Note that some Robust Details may not give zero U-value for party wall thermal bypass, check the details carefully.

Masonry Separating (Party) Walls

| England & Wales | Scotland | |

| E-WM-01 | E-WM-16 | V-WM-11 |

| E-WM-02 | E-WM-18 | V-WM-19 |

| E-WM-03 | E-WM-19 | V-WM-21 |

| E-WM-04 | E-WM-21 | |

| E-WM-05 | E-WM-22 | |

| E-WM-06 | E-WM-25 | |

| E-WM-10 | E-WM-26* | |

| E-WM-11 | E-WM-29 | |

| E-WM-12 | E-WM-31 | |

| E-WM-13 |

Timber Separating (Party) Walls

| England & Wales | Scotland | |

| E-WT-01 | V-WT-01 | |

| E-WT-02 | V-WT-02 |

For further information see our technical brochure in the Documents section. Alternatively please contact URSA Technical Department.

Industry information

Sources of useful additional information

|

Robust Details Ltd Alternative to pre-completion sound testing |

More info |